OUR PROCESS

All the milk our cows produce is pumped a short distance of 20 feet directly into our on-site processing plant, where we process and bottle up to 5 times per week

We process using a low-temp pasteurization method.

In this method, the milk is brought up to a 160° Fahrenheit

and held there for 30 minutes. This ensures any potentially

harmful bacteria is completely removed, yet still preserves all the

flavor and beneficial enzymes and proteins.

For a smooth finish, all of our milk is homogenized.

It has a natural shelf life of 14 days,

and always needs to be refrigerated.

We proudly bottle our milk in glass half gallon bottles.

OUR herd

We wouldn’t be a micro dairy

without our cows.

We believe our cows quality of life and health comes before milk stats and production information. Our herd of less than 100 is milked twice a day in our 125 year old very large, red barn. As much as the Minnesota weather allows, they are out roaming over 100 acres of pasture and are eagerly waiting outside the barn every morning and evening when it is time to milk.

We have a multigenerational herd and proudly raise our calves to eventually join their mother and aunts in our milking herd.

Our friendly cows live a happy, care-free life.

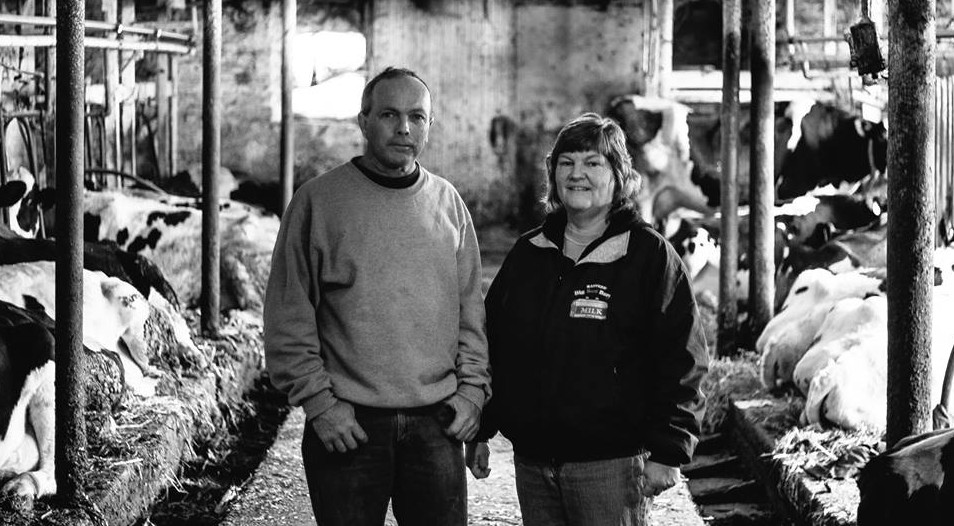

OUR family

Our micro dairy is not just family owned,

it is family run.